Crusher

- Home

- >>

- Products

- >>

- Crusher

- >>

- View Details

Got any Questions?

CALL US NOW

Mobile: 0086 186 5335 4363

Tel / Fax: 0086 533 3588750

Email: info@crusher-world.com

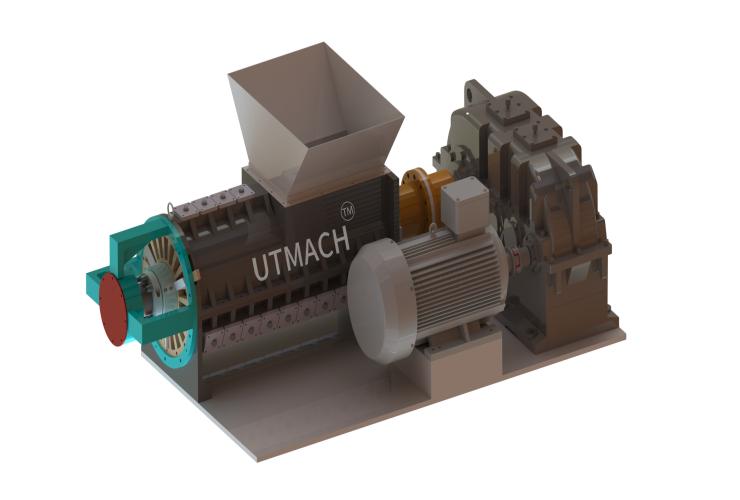

Spiral Crusher

The Spiral Crusher is a multi-functional crushing equipment developed by UTMACH, combining spiral extrusion and shearing principles. It is specially designed for crushing elastic, tough, and mixed materials. With a compact structure and low power consumption, it ensures high output and long service life.

Features:

Wide application range and strong adaptability

High productivity and efficient crushing

Long-lasting, wear-resistant blades

Spiral compression and shearing for superior crushing results

Low-speed operation with reduced noise and energy use

Adjustable discharge openings for customizable particle size

Applicable Materials:

Natural rubber, synthetic rubber, and latex products

Inner and outer tires, rubber mats, soles, seals, gaskets

Rubber scraps, conveyor belts

PE foam, EVA, and other elastic plastics

Working Principle:

The machine consists of a rotating shaft with multiple movable blades and stationary blades fixed on the housing. During operation, the slow-rotating shaft repeatedly cuts and compresses the material, pushing it forward under high pressure. The material is rolled, kneaded, and ground within the chamber, then extruded through elongated discharge holes. A scraper at the outlet performs secondary cutting to ensure uniform and fine particles. The discharge holes can be adjusted to control the final particle size.

Note:

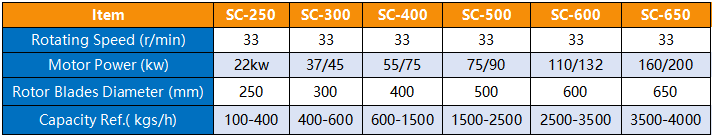

1. The voltage and motor power about the power supply can be selected by the customer’s specific requirements.

2. The Crusher capacity can be influenced by the material composition and output size.

We provide Customized Machines. The above specifications are only for reference and subject to change without prior notice, please confirm with our sales representative when making order.

Previous:Nothing

Next:Mobile Crusher Line